The integration of smart finders into original equipment manufacturer projects represents a significant advancement in asset tracking and location technology. As businesses across industries seek more efficient ways to monitor valuable equipment, inventory, and personal belongings, smart finders have emerged as a versatile solution that can be seamlessly incorporated into various OEM applications. These compact tracking devices offer real-time location capabilities, making them invaluable for manufacturers looking to enhance their products with advanced tracking functionality.

Modern manufacturing environments demand sophisticated tracking solutions that can withstand industrial conditions while providing accurate location data. Smart finders designed for OEM integration must meet stringent quality standards and offer customization options that align with specific project requirements. The technology behind these devices has evolved significantly, incorporating advanced sensors, extended battery life, and robust connectivity options that make them suitable for diverse industrial applications.

The strategic implementation of smart tracking technology into OEM projects requires careful consideration of technical specifications, integration methods, and long-term scalability. Manufacturers must evaluate various factors including power consumption, communication protocols, environmental resistance, and compatibility with existing systems. Understanding these elements is crucial for successful deployment and optimal performance in real-world applications.

Technical Integration Fundamentals

Hardware Compatibility Requirements

Successful integration of smart finders into OEM projects begins with understanding the fundamental hardware compatibility requirements. The physical dimensions of tracking devices must align with the host equipment's design constraints, ensuring seamless installation without compromising the original product's functionality. Modern smart finders offer various form factors, from ultra-compact chips to more robust enclosures suitable for industrial environments.

Power management represents another critical aspect of hardware compatibility. OEM integrators must consider whether the smart finder will operate on the host device's power supply or require independent battery systems. Advanced tracking solutions now offer flexible power options, including energy harvesting capabilities and ultra-low power consumption modes that extend operational life significantly.

Environmental specifications play a crucial role in determining the appropriate smart finder for specific OEM applications. Industrial equipment often operates in challenging conditions involving temperature extremes, moisture, vibration, and chemical exposure. The selected tracking technology must demonstrate proven resilience to these environmental factors while maintaining consistent performance and reliability.

Communication Protocol Selection

The choice of communication protocols significantly impacts the effectiveness of smart finder integration in OEM projects. Bluetooth Low Energy technology offers excellent power efficiency and is particularly suitable for applications requiring frequent proximity-based interactions. However, for broader coverage requirements, cellular-based solutions provide global connectivity with real-time tracking capabilities.

WiFi-enabled smart finders present an excellent middle ground for OEM applications in environments with established wireless infrastructure. These devices can leverage existing network connections to provide accurate location data while minimizing additional communication costs. The selection process must consider factors such as coverage area, data transmission frequency, and integration with existing network security protocols.

Emerging technologies like LoRaWAN and NB-IoT offer promising alternatives for OEM integration, particularly in applications requiring long-range communication with minimal power consumption. These technologies enable smart finders to operate effectively in remote locations where traditional cellular coverage may be limited or cost-prohibitive.

Customization and Design Considerations

Brand Integration Strategies

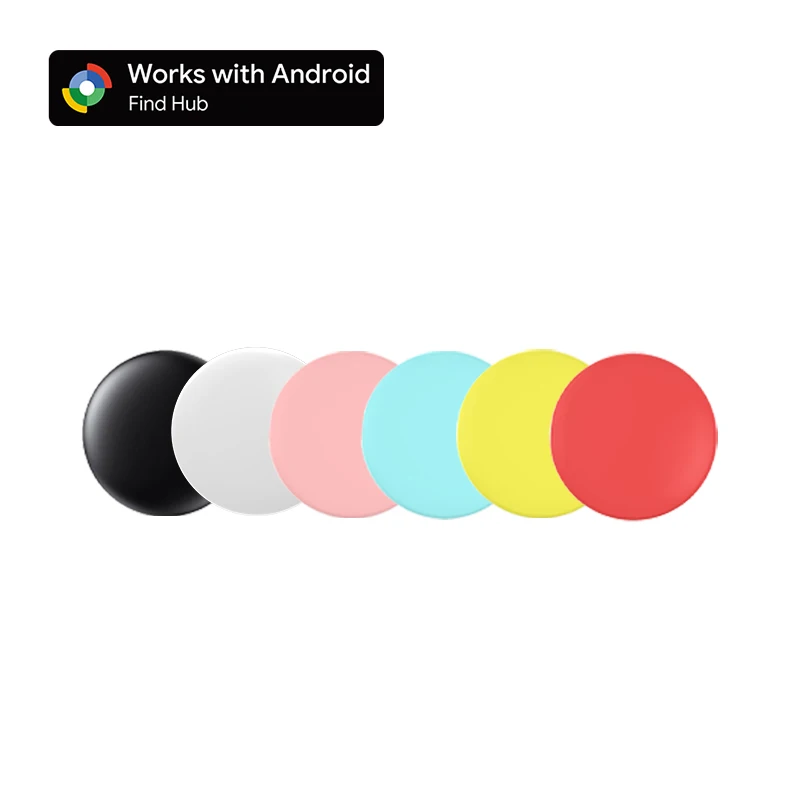

Effective brand integration requires careful attention to both aesthetic and functional elements of smart finder design. OEM partners typically require tracking devices that seamlessly blend with their product's visual identity, incorporating custom colors, logos, and form factors that maintain brand consistency. Advanced manufacturing techniques now enable high-quality custom enclosures that protect internal components while delivering professional appearance.

Software customization extends beyond physical appearance to include user interface elements and mobile application branding. Smart finders integrated into OEM projects can feature custom app interfaces that align with the manufacturer's digital ecosystem, providing users with a cohesive experience across all touchpoints. This level of customization strengthens brand recognition and customer loyalty.

Packaging and documentation customization ensures that end users receive a complete branded experience from product unboxing through initial setup and ongoing operation. OEM integrators benefit from comprehensive white-label solutions that include custom packaging design, branded instruction materials, and technical support resources aligned with their corporate identity.

Functional Customization Options

Modern smart finders offer extensive functional customization capabilities that enable OEM partners to tailor tracking solutions to specific application requirements. Geofencing parameters can be adjusted to match unique operational needs, with custom alert systems that integrate with existing notification infrastructure. These customizations ensure that tracking data provides actionable insights relevant to each specific use case.

Sensor integration represents another valuable customization opportunity for OEM applications. Smart finders can incorporate additional sensors such as temperature monitors, accelerometers, or humidity sensors to provide comprehensive environmental data alongside location information. This multi-sensor approach creates value-added solutions that differentiate OEM products in competitive markets.

Data reporting and analytics customization enables OEM partners to provide their customers with insights that align with industry-specific requirements. Custom dashboard development and API integration ensure that tracking data flows seamlessly into existing business intelligence systems, maximizing the value derived from smart finder implementation.

Implementation Strategies and Best Practices

Project Planning and Timeline Management

Successful smart finder integration requires comprehensive project planning that addresses technical, logistical, and commercial considerations. The development timeline must account for prototyping phases, regulatory compliance testing, and production scaling requirements. Early engagement with smart finder suppliers ensures adequate time for customization development and quality assurance processes.

Risk assessment and mitigation strategies form essential components of effective project planning. Potential challenges such as supply chain disruptions, regulatory changes, or technical compatibility issues must be identified and addressed proactively. Establishing contingency plans and alternative supplier relationships helps maintain project momentum despite unforeseen obstacles.

Milestone definition and progress tracking enable systematic project management that keeps integration efforts on schedule and within budget. Regular review cycles and stakeholder communication ensure that all parties remain aligned on project objectives, technical specifications, and delivery expectations throughout the implementation process.

Quality Assurance and Testing Protocols

Comprehensive testing protocols ensure that integrated smart finders meet performance specifications and reliability requirements in real-world operating conditions. Environmental testing must validate device performance across expected temperature ranges, humidity levels, and mechanical stress conditions. These tests verify that tracking accuracy and communication reliability remain consistent throughout the product lifecycle.

Electromagnetic compatibility testing verifies that smart finders operate properly within the electromagnetic environment of the host equipment without causing interference or experiencing degraded performance. This testing is particularly critical for OEM applications involving sensitive electronic equipment or communication systems where electromagnetic interference could impact primary functionality.

Battery life validation testing ensures that power consumption projections align with actual operational requirements. Long-term testing protocols simulate real-world usage patterns to verify that smart finders maintain functionality throughout their intended operational lifespan. This validation is essential for establishing accurate maintenance schedules and warranty terms.

Market Applications and Industry Solutions

Industrial Equipment Tracking

Industrial equipment manufacturers increasingly recognize the value of integrating smart finders into their products to provide customers with enhanced asset management capabilities. Construction equipment, manufacturing machinery, and specialized tools benefit significantly from real-time location tracking that helps prevent theft, optimize utilization, and streamline maintenance scheduling.

The integration of tracking technology enables equipment manufacturers to offer value-added services such as predictive maintenance, usage analytics, and theft recovery assistance. These services create new revenue streams while strengthening customer relationships through enhanced support offerings. Smart finders provide the foundational data necessary to deliver these advanced services effectively.

Fleet management applications represent a particularly compelling use case for smart finder integration in industrial equipment. Tracking devices enable comprehensive fleet visibility, route optimization, and operational efficiency improvements that deliver measurable return on investment for equipment owners and operators.

Consumer Product Enhancement

Consumer product manufacturers are discovering innovative ways to incorporate smart finders into everyday items, creating enhanced user experiences and competitive differentiation. Luggage manufacturers, automotive accessory companies, and personal electronics brands successfully integrate tracking technology to address common consumer pain points related to lost or misplaced items.

The pet industry has embraced smart finder integration with particular enthusiasm, as pet owners increasingly seek reliable solutions for monitoring their animals' whereabouts. Smart collars and tracking accessories provide peace of mind while enabling new services such as activity monitoring and health tracking that appeal to health-conscious pet owners.

Electronics manufacturers integrate tracking capabilities into high-value consumer products such as laptops, tablets, and professional equipment to reduce theft risk and improve recovery rates. This integration adds significant value for business customers who require asset tracking capabilities for inventory management and security compliance.

Cost Analysis and Return on Investment

Implementation Cost Factors

Understanding the complete cost structure of smart finder integration enables OEM partners to make informed decisions about implementation strategies and pricing models. Initial development costs include hardware customization, software development, testing, and regulatory certification expenses. These upfront investments must be balanced against projected sales volumes and market penetration expectations.

Ongoing operational costs encompass connectivity fees, customer support, warranty obligations, and product maintenance requirements. Cellular-based tracking solutions typically involve monthly service fees that must be factored into the total cost of ownership. However, these costs are often offset by the value customers derive from real-time tracking capabilities and theft protection.

Volume pricing considerations significantly impact the economic viability of smart finder integration projects. Suppliers typically offer substantial cost reductions for large volume commitments, making integration more attractive for high-volume OEM applications. Careful analysis of projected demand and pricing elasticity helps optimize the cost-benefit equation.

Revenue Enhancement Opportunities

Smart finder integration creates multiple revenue enhancement opportunities that extend beyond initial product sales. Subscription-based tracking services provide recurring revenue streams that improve long-term profitability and customer lifetime value. These services can include premium features such as extended history, advanced analytics, and priority support.

Insurance partnerships represent another valuable revenue opportunity for OEM companies offering tracking-enabled products. Insurance providers often offer premium discounts for tracked items, creating additional customer value while potentially generating referral income for OEM partners. This collaboration benefits all parties by reducing claim costs and improving risk management.

Data monetization opportunities emerge from the comprehensive tracking and usage data generated by integrated smart finders. Anonymized aggregate data can provide valuable insights for market research, product development, and strategic planning purposes. However, data monetization strategies must carefully balance revenue potential with privacy concerns and customer trust considerations.

Regulatory Compliance and Certification

Wireless Communication Standards

Compliance with wireless communication standards represents a fundamental requirement for smart finder integration in OEM projects. Federal Communications Commission regulations in the United States, European Telecommunications Standards Institute requirements in Europe, and similar regulatory frameworks worldwide govern the operation of wireless tracking devices. Obtaining proper certifications ensures legal market access and prevents costly compliance issues.

Radio frequency emission limits must be carefully considered when integrating smart finders into existing products. The combined electromagnetic signature of the host device and tracking technology must remain within acceptable limits to avoid interference with other electronic systems. Pre-compliance testing during the development phase helps identify potential issues before formal certification processes begin.

International certification requirements vary significantly across different markets, necessitating comprehensive compliance planning for global OEM projects. Working with experienced certification partners familiar with multiple regulatory frameworks helps streamline the approval process and ensures consistent compliance across target markets.

Data Privacy and Security Requirements

Data privacy regulations such as the General Data Protection Regulation in Europe and the California Consumer Privacy Act in the United States establish strict requirements for handling personal location data. OEM partners must implement comprehensive privacy policies and technical safeguards to ensure compliance with applicable regulations while maintaining user trust and satisfaction.

Cybersecurity considerations become increasingly important as smart finders collect and transmit sensitive location information. Robust encryption protocols, secure authentication mechanisms, and regular security updates help protect against unauthorized access and data breaches. Industry-standard security frameworks provide guidance for implementing appropriate protection measures.

User consent management systems must be implemented to ensure that location data collection and processing activities comply with privacy regulations. Clear consent mechanisms, transparent data usage policies, and easy opt-out procedures demonstrate commitment to privacy protection while enabling beneficial tracking services.

Future Technology Trends and Innovations

Emerging Tracking Technologies

The evolution of tracking technology continues to create new opportunities for smart finder integration in OEM projects. Ultra-wideband technology promises significantly improved indoor positioning accuracy, enabling applications that require precise location determination within complex environments. This technology is particularly valuable for industrial applications where meter-level accuracy is insufficient.

Artificial intelligence integration enables smart finders to provide predictive insights and automated decision-making capabilities. Machine learning algorithms can analyze location patterns to predict equipment maintenance needs, optimize routing, or detect anomalous behavior that may indicate theft or misuse. These intelligent features add substantial value for OEM customers seeking advanced analytics capabilities.

Energy harvesting technologies are advancing rapidly, potentially eliminating battery replacement requirements for many smart finder applications. Solar, kinetic, and thermal energy harvesting systems enable perpetual operation in appropriate environments, reducing maintenance costs and improving long-term sustainability. These innovations are particularly attractive for industrial applications where device accessibility is limited.

Integration with Internet of Things Ecosystems

The convergence of smart finders with broader Internet of Things ecosystems creates opportunities for comprehensive connected solutions that extend beyond simple location tracking. Integration with smart building systems, industrial automation platforms, and enterprise resource planning systems enables smart finders to contribute to holistic operational optimization strategies.

Edge computing capabilities allow smart finders to process data locally, reducing bandwidth requirements and improving response times for time-critical applications. This distributed processing approach enables more sophisticated real-time decision making while reducing dependence on cloud connectivity for basic functionality.

Blockchain integration offers potential solutions for secure, decentralized tracking data management that addresses privacy concerns while enabling transparent audit trails. These technologies may become increasingly important for applications requiring verifiable location histories or secure chain-of-custody documentation.

FAQ

What are the main technical considerations when integrating smart finders into existing OEM products

The primary technical considerations include power supply compatibility, communication protocol selection, physical form factor constraints, and electromagnetic compatibility. OEM integrators must ensure that the smart finder operates reliably within the host device's technical specifications while maintaining optimal tracking performance. Environmental durability requirements and regulatory compliance also significantly impact technical design decisions.

How do customization options affect the cost and timeline of smart finder integration projects

Customization requirements typically increase both development costs and project timelines, but they also enable greater product differentiation and customer value. Hardware modifications generally have the most significant impact on cost and schedule, while software customizations offer more flexibility with shorter development cycles. The extent of customization should be balanced against projected sales volumes and competitive requirements to optimize return on investment.

What ongoing support and maintenance requirements should OEM partners expect after smart finder integration

Ongoing support requirements include software updates, connectivity service management, customer technical support, and warranty service coordination. OEM partners should establish clear support agreements with smart finder suppliers that define responsibilities for each aspect of post-deployment support. Regular firmware updates and security patches are essential for maintaining optimal performance and protecting against evolving cybersecurity threats.

How can OEM companies evaluate the return on investment for smart finder integration projects

ROI evaluation should consider multiple factors including initial development costs, ongoing operational expenses, projected sales impact, and potential new revenue streams from tracking services. Market research indicating customer willingness to pay premium prices for tracking-enabled products provides crucial input for ROI calculations. Long-term benefits such as improved customer satisfaction, reduced warranty claims, and competitive differentiation should also be factored into comprehensive ROI assessments.

Table of Contents

- Technical Integration Fundamentals

- Customization and Design Considerations

- Implementation Strategies and Best Practices

- Market Applications and Industry Solutions

- Cost Analysis and Return on Investment

- Regulatory Compliance and Certification

- Future Technology Trends and Innovations

-

FAQ

- What are the main technical considerations when integrating smart finders into existing OEM products

- How do customization options affect the cost and timeline of smart finder integration projects

- What ongoing support and maintenance requirements should OEM partners expect after smart finder integration

- How can OEM companies evaluate the return on investment for smart finder integration projects